Your cart is currently empty!

From Cracks to Wounds: Repairing Leather as Good as New

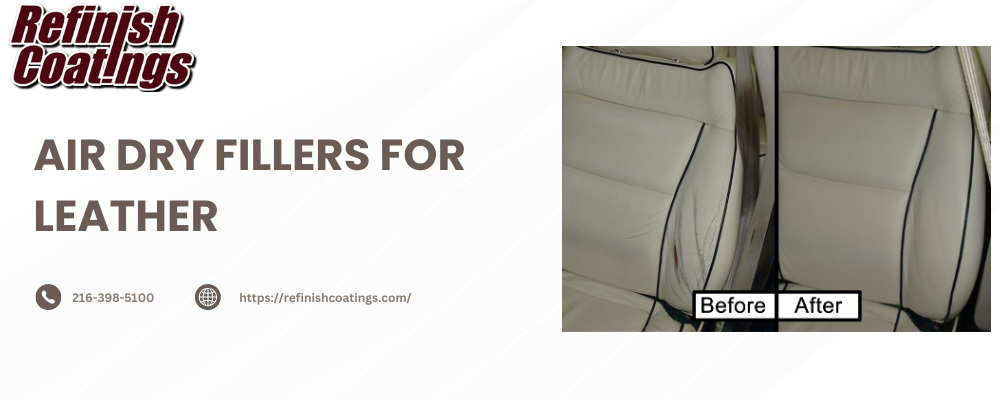

Leather is a natural product, and as with most natural products, over time it can crack, wound (cut, burn, tear) and generally deteriorate. However, unlike vinyl or other materials, leather has the unique ability to heal when treated correctly. Old cracks and blemishes can easily be repaired using various techniques and materials designed to make the leather look like the day it was delivered from the showroom.

This blog gives you the complete low-down on repairing leather that is suffering from cracks and wounds. From cleaning to sanding, sub-patches and fillers, we present our recommendations of dos and don’ts for proper leather repair.

The Sub-patch

If the leather has suffered a wound (cut, burn, or tear) and the affected area is prone to excess wear and tear, sub-patching adds the necessary strength giving the repair its best change to last the life of the piece.

Repair compounds or “fillers” as they are popularly known offer some strength at best to damaged leather. However, in high use or high stress areas, without sub-patching, the repair will likely fail. Repair compounds are applied to fix the wound, not restore the tensile strength of damaged leather.

For example, the side thigh supports of a car seat get the most amount of use and abuse (during entry and exit). Over the years, the leather will fade and in worst case scenario, develop a tear. Typically, the torn leather will require a sub-patch. Other vulnerable car seat areas include, the rear cushions, the back-rest, and the armrest.

Applying the Filler

Overtime leather will present a void, gouge or depression. Leather filler is intended to fill in a wound and bring the void up to the level of the surrounding leather. Scrapes, scratches, gouges, burns, cuts, open scars and others, all present depressions or voids that will stand out it your simply apply color over them. This makes the filler compound an essential ingredient in leather repair.

As with all resins, leather fillers can air-cure. However, heat from a heat gun or hair dryer will accelerate the curing cycle. Make sure the compound you are applying can be sanded. When the fill is fully dry, there may be edges or ridges that have to be knocked down to render a smooth, even texture.

Sanding the Filler

If there is one stage in leather refinishing that often goes unnoticed, it will have to be sanding. Undoubtedly the most uneventful part of refinishing process, proper sanding can lead to an excellent leather finish. To know whether the affected area requires sanding, touch the area to see if it is rough or has burs and snags that catch when you move your hand across the area. Gently sand with 400 grit sand paper until the surface feels smooth. Once the sanding process is complete, wipe down the surface to remove dust residue that may have been left behind during sanding.

Use only High-Quality Filler

If you aren’t using an air dry crack filler specifically engineered for leather, the filler will tend to gradually stiffen over time. If its does, you can also expect it to crack and split. A poorly engineered filler relies on moisture for its flexibility. Leather is absorbent. As the sidewall of the leather wound draws the moisture out of the filler, it shrinks and stiffens, losing flexibility in the process.

Recommendations For the Best Finish

At Refinish Coatings we recommend the air dry crack filler as a high-quality compound specifically designed for lehttps://refinishcoatings.com/ather. The filler comes in two colors, black and white and is meant to fill voids that are 1/16″ and finer. The compound has fast drying capabilities and can be sanded using a 320-600 grit sandpaper.

We recommend applying small amounts of filler to affected areas and letting the filler completely cure before applying a second coat. Applying the air dry crack filler correctly will lead to a wonderful leather finish.

Final Thoughts

If you found this blog helpful, stay tuned for upcoming content around leather finishing and our recommended products to get the best finish. If you would like to buy the air dry crack filler, clink here. At Refinish Coatings, we are committed to providing only the highest quality finishing products that bring value to your automotive and furniture repair business. If you would like an in-depth overview on any of our products, feel free to get in touch with us.